Ramming of steel pipes

The technology is used for the construction of steel cases for various engineering communications. The diameter of the pipes is up to 1400 mm, length is up to 80 m. The use of the kit is also suitable for vertical dipping of metal piles. The consolidation of soil massifs, the installation of sheet piling is performed by plugging metal pipes into the ground. Pipes are rammed vertically or under the required slope. Diameter of steel pipes varies between 150-600 mm, immersion depth is up to 10 m, possible with or without cleaning.

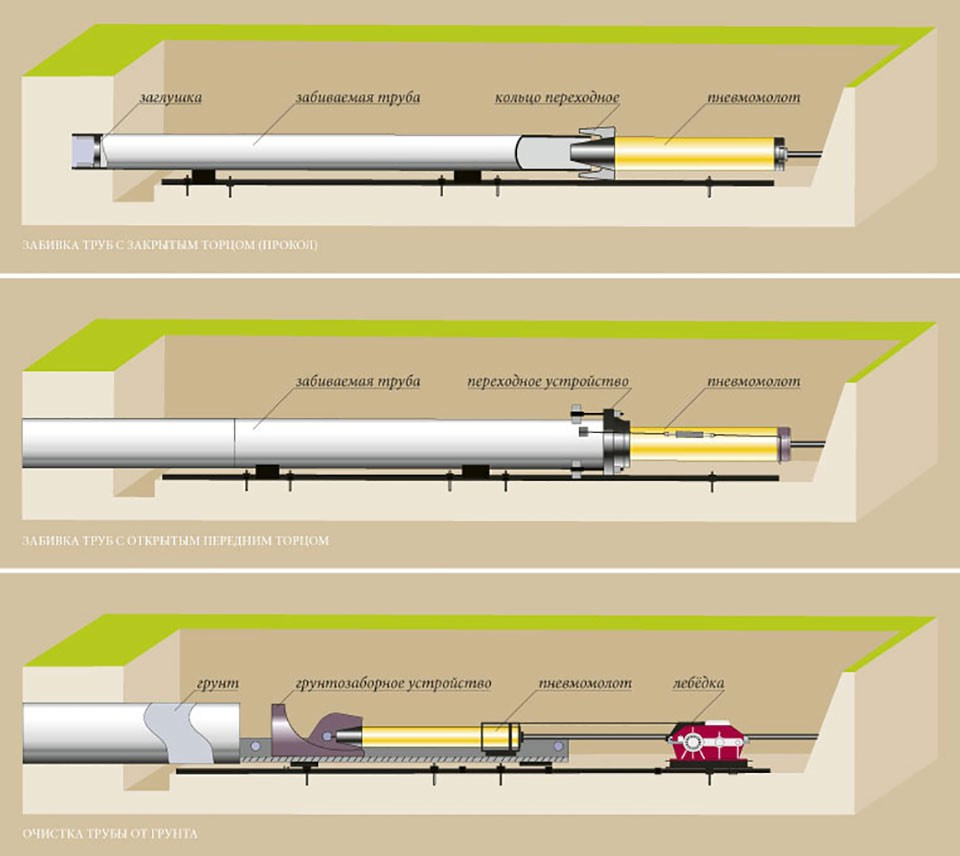

Principle of operation:

Ramming of pipes in the ground is performed both with a closed (puncture) and with an open front end. Puncture is possible in all types of compressible soils. To improve the accuracy of the laying and the speed of immersion, depending on the characteristics of the soil, various head ends of the hammered pipe and special technological methods are used.

The technology of fixing pipes with an open front end allows increasing the diameter of the laid pipes due to a decrease in the drag of the ground, compared to fixing with a closed end. Pipes are fixed for the entire length of the transition, and then cleaned of the soil by a self-propelled soil-collecting device, or fixed in sections with alternating cleaning of each section.

Composition of the kit

- Pneumatic hammer for ramming pipes;

- Pneumatic hammer of soil-collecting device;

- Transition device;

- Pneumatic winch;

- Soil-collecting device (bailer).